On Board Gasketing

On Board Gasketing

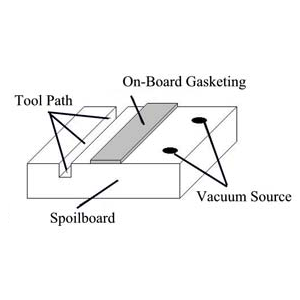

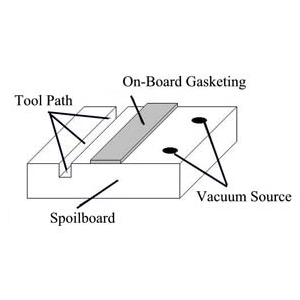

This style of fixture uses sealants that range in thickness and are coated on one side with a pressure sensitive adhesive. The On Board group was created for quick runs and job-shop type applications. If investing the time needed to construct a dedicated spoilboard does not make efficiency sense, yet you still require a strong vacuum pull to hold your parts, then On Board gasketing is your answer.

Start by adhering the foam gasket onto the surface of your fixture; position it parallel and fairly close to the interior side of the previously cut tool path channel. Next, create adequate vacuum holes inside this sealed border; when the vacuum system is engaged the spoilboard will maintain a vacuum chamber using 1) the walls of the compressed sealant, 2) the underside of your substrate and 3) the top surface of your spoilboard.

Two Rules for On Board sealants: Thinner is better than thicker and higher density is better than lower density.